Understanding TTHS Bolts

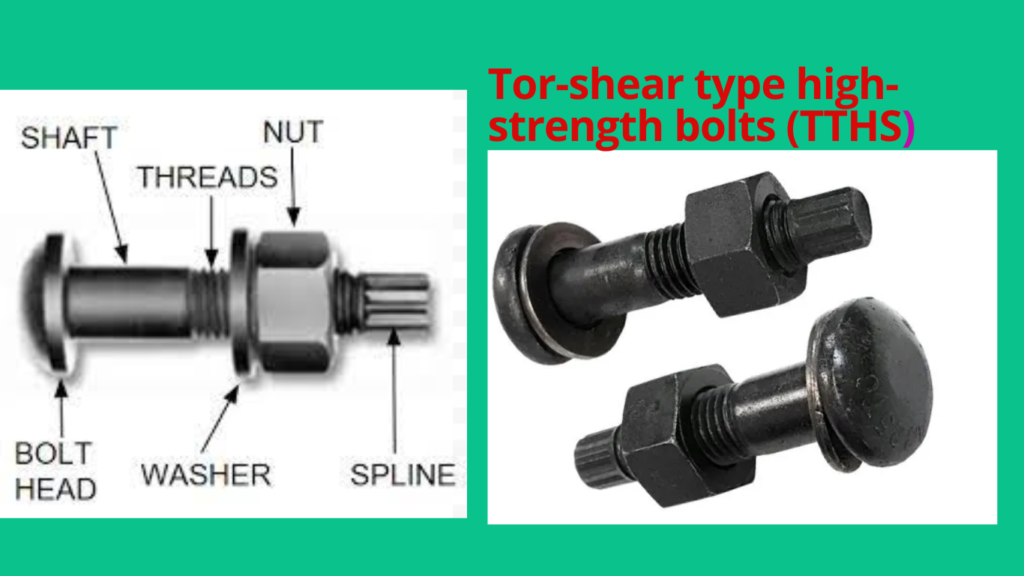

TTHS bolts, also known as Tor-shear type high-strength bolts, represent the pinnacle of engineering brilliance. Recognizable by their distinctive design and properties, these bolts play a crucial role across different industries. This detailed guide takes you into the realm of TTHS bolts, uncovering their unique features, diverse applications, and explaining why they are indispensable for a wide range of projects.

Table of Contents

Key Features of Tor-shear type high-strength bolts

High-Strength Steel

One of the defining characteristics of TTHS bolts is their composition. These bolts are crafted from high-strength steel, which enables them to withstand substantial loads and stresses. The high-strength steel used in TTHS bolts ensures that they have the durability and resilience needed for critical applications. Whether it’s a bridge supporting heavy traffic or a high-rise building with thousands of occupants, TTHS bolts provide the necessary strength to keep structures secure.

Tension Control

Another essential feature of Tension control bolts is their unique design that allows for precise tension control during installation. Unlike traditional bolts, where tightening can be challenging to control accurately, TTHS bolts offer a reliable and efficient solution. The tension control mechanism ensures that the bolt is tightened to the required level of tension, minimizing the risk of under or over-tightening. This level of precision is particularly crucial in critical applications where structural integrity is of utmost importance.

Dome-Shaped Head

If you’ve ever come across a TTHS bolt, you may have noticed its distinctive dome-shaped head. This design sets them apart from conventional hexagonal bolts. The domed head of TTHS bolts serves a purpose beyond aesthetics. It requires a specialized wrench for installation, ensuring that only professionals with the necessary tools can work with these specialized fasteners. This design consideration adds an extra layer of safety and reliability to projects that rely on TTHS bolts.

Deformation Mechanism

Once TTHS bolts are correctly installed, they undergo a controlled deformation process. The extension of the bolt is sheared off due to torque, resulting in a secure and reliable connection. This deformation mechanism provides enhanced strength and stability to the fastened joint. Whether it’s a structural component or a piece of heavy machinery, the controlled deformation of TTHS bolts ensures that connections remain intact even under extreme conditions.

Spline for Tension Gauge

One of the most practical features of TTHS bolts is the presence of a spline that serves as a tension gauge. Consisting of ridges or grooves along the shaft of the bolt, the spline provides a clear indication of when the precise tension has been achieved during installation. This feature eliminates guesswork and ensures that the bolt is tightened to the specific requirements of the project. The use of the spline as a tension gauge adds another layer of control and accuracy when working with TTHS bolts.

TTHS Bolts Applications

TTHS bolts find widespread use across diverse industries owing to their exceptional properties and reliability. Let’s explore some of the key sectors where TTHS bolts are indispensable:

Source:-Unytite USA Youtube Channel

1. Construction

In the construction industry, TTHS bolts play a critical role in securing vital structural elements. From bridges to high-rise buildings and stadiums, TTHS bolts are extensively employed in projects where their high tensile strength and reliability are crucial. These bolts provide the necessary strength and stability to support heavy loads and ensure the safety of structures and those who use them.

2. Manufacturing

Manufacturers rely on TTHS bolts to fasten heavy machinery and equipment securely. These bolts play a vital role in the assembly of machines, ensuring that they remain stable during operation. The exceptional strength and reliability of TTHS bolts contribute to both the safety and productivity of manufacturing processes by minimizing the risks associated with loose or weak connections.

3. Automotive

In the automotive sector, TTHS bolts are instrumental in the assembly of vehicles. From securing critical components such as engine mounts and suspension parts to fastening body panels, TTHS bolts provide the necessary strength and reliability to ensure the overall safety and performance of automobiles. These bolts are designed to withstand the vibrations and stresses associated with vehicle operation, making them an essential component in the automotive manufacturing process.

4. Aerospace

The aerospace industry demands precision, safety, and reliability like no other. It is in this industry where TTHS bolts find a home. These bolts are integral in the assembly of aircraft and spacecraft, where their exceptional strength and reliability are vital. From holding together critical aerospace components to ensuring the structural integrity of the vehicles, TTHS bolts play a crucial role in maintaining the safety and functionality of aerospace technology.

Types of High-Strength Bolts

High-strength bolts for steel structures can be categorized into two main types based on their structure and construction method:

1. Friction Connection

Friction connection high-strength bolts rely on the transmission of force through friction between connected members. The coefficient of friction is determined by the surface treatment of materials and contact surfaces of the connected members. This type of bolt connection is well-suited for applications where dynamic loads, such as wind or vibrations, are involved.

2. Pressure Connection

Pressure connection high-strength bolts, on the other hand, only require rust-proofing on the connection surface. These bolts create a solid connection by applying pressure, ensuring that the force is distributed evenly between the connected members. Pressure connection bolts are ideal for static load-bearing applications where stability and long-term durability are essential.

Bolt Joint Components

A bolt joint consists of three essential components: a bolt, a nut, and a washer. These components work together to create a secure and reliable connection. When working with high-strength bolts, it is crucial to adhere to the specified standards and guidelines for construction and arrangement requirements. By using the appropriate bolt, nut, and washer combination, and following the recommended installation procedures, the full potential of high-strength bolts can be harnessed.

Torsional Shear-type High-Strength Bolts

Torsional shear-type high-strength bolts share mechanical characteristics with general high-strength bolts. However, they distinguish themselves by controlling pretension through the section at the cut of the bolt head. This unique feature ensures precise and reliable tension in critical applications. The torsional shear mechanism eliminates the need for complex torque calculations, providing a simpler and more efficient installation process without compromising on strength and reliability.

In summary, TTHS bolts, or Tor-shear type high-strength bolts, represent a pinnacle of fastener engineering. Their high-strength steel construction, tension control capabilities, and precise torque-based installation make them a top choice for critical applications across various industries. Whether in construction, manufacturing, automotive, or aerospace, TTHS bolts are a testament to engineering excellence, providing the strength and reliability needed to support essential projects worldwide.

For More details Please Visit this Website:- https://www.tcbolts.com/en/