Welding defects are a major problem in both building and manufacturing, as they compromise the structural integrity and strength of everything from furniture to skyscrapers. However, there are difficulties with this complicated procedure, especially with welding flaws. If these defects are not found and fixed right away, they have the potential to seriously compromise the longevity and safety of welded structures. This detailed guide aims to help you understand common welding flaws by explaining what causes them, how to spot them, and how to fix them. We’ll explore the 6 most commonly found issues.

Table of Contents

Types of Welding Defects

The weld defects can be divided into 2 types.

- External weld defects:- These are the kinds of faults that show up at the weld’s surface. Visual examination and non-destructive testing (NDT) methods such as the Magnetic Particle Test (MPT) and the Dye Penetrants Test (DPT) make it easy for the naked eye to identify these problems. External welding faults include overlaps, porosity, cracks, and spatter.

- Internal weld defects:- These flaws are present inside the weld deposit. These flaws are invisible to the naked eye and cannot be found using NDT or visual examination, which are methods used to find external welding flaws. Other non-destructive testing (NDT) techniques, such as radiography testing (RT)and ultrasonic testing (UT), are used to find these kinds of faults. Examples of internal welding flaws include slag inclusions, partial penetration, and incomplete fusion.

This guide covers the 6 most common weld defects occurring in weld whether it’s an external or internal weld defect.

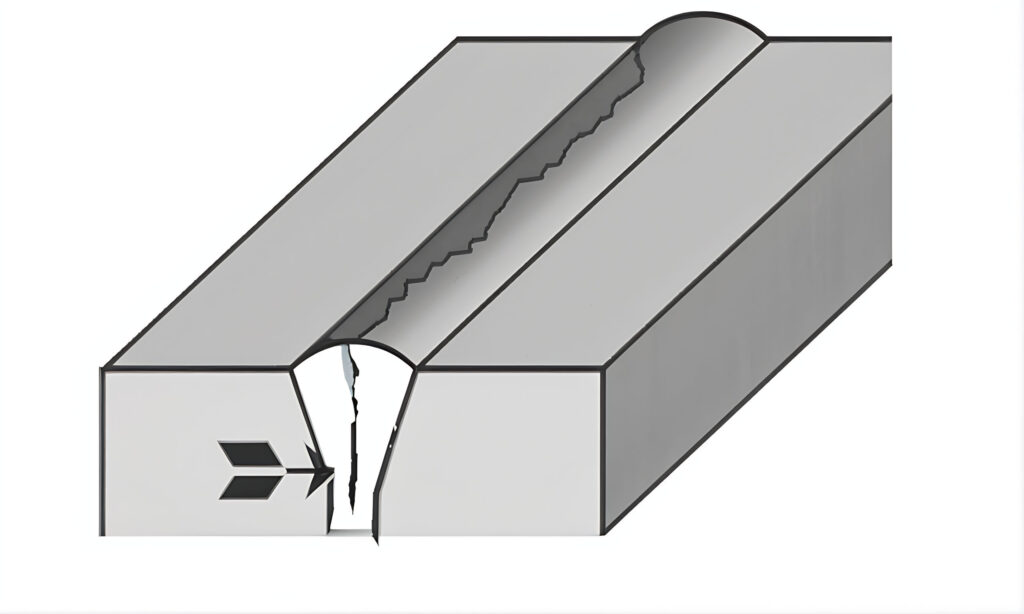

1. Cracks:-

Cracks are among the most severe welding defects due to their potential to compromise structural integrity. They can appear in various forms, including longitudinal, transverse, crater, and heat-affected zone (HAZ) cracks. Depending on the temperature at which they occur, cracks can be:

- Hot Cracks: These occur as the weld cools down after being melted. They happen when the temperature is super high, usually over 1000 degrees Celsius. There are two kinds: solidification cracks, which form due to impurities or disruptions in heat flow, and liquation cracks, caused by excessive heating that melts certain components with lower melting points.

- Cold Cracks: These sneaky cracks appear days after welding, even after the metal has solidified. They often run parallel to the fusion boundary. Factors like low temperatures, high stresses, lack of preheating, or high hydrogen content can cause them. Residual tensile stress might also push them away from the fusion boundary.

Root Causes:

- Poor Welding Technique: Inconsistent arc control or improper filler metal deposition.

- Incorrect Material Selection: Mismatched materials with varying thermal expansion rates.

- Excessive Cooling Rates: Rapid cooling, especially in thick materials.

Elimination Strategies:

- Adherence to Welding Parameters: Strictly follow recommended parameters for current, voltage, and travel speed.

- Preheating/Post-Weld Heat Treatment: This is especially crucial for materials prone to cracking.

- Material Compatibility: Ensure compatibility and matching coefficients of thermal expansion.

2. Porosity:-

Porosity manifests as tiny cavities or holes within the weld metal, caused by trapped gases during the solidification process.

Root Causes:

- Contamination: Presence of moisture, oil, or grease in the weld area.

- Incorrect Welding Technique: Improper shielding gas flow or incorrect electrode angles.

- Damp Electrodes: Use of electrodes exposed to moisture.

Elimination Strategies:

- Quality Filler Materials: Use dry, high-quality filler materials to minimize gas entrapment.

- Thorough Cleaning: Clean the weld surface meticulously to remove contaminants.

- Optimized Shielding Gas Flow: Adjust gas flow rates to prevent air infiltration.

3. Incomplete Fusion and Penetration:-

Incomplete fusion happens when the weld metal doesn’t properly blend with the base metal or previous weld layers. On the other hand, incomplete penetration means the weld doesn’t go all the way through the joint’s thickness. Both of these issues can weaken the joint and ultimately lead to joint or weld failure.

Root Causes:

- Incorrect Welding Parameters: Inadequate heat input or incorrect electrode angle.

- Poor Welding Technique: Insufficient filler metal deposition or improper manipulation.

- Lack of Preheating: This is especially critical for thicker materials.

Elimination Strategies:

- Proper Heat Input: Adjust parameters to ensure sufficient heat for proper fusion.

- Correct Electrode Angle: Maintain the correct angle to facilitate proper penetration.

- Preheating: This is especially crucial for thicker materials or challenging joint configurations.

4. Undercutting:-

Undercutting is a groove that forms at the weld toe or root, weakening the weld’s edge. It often results from excessive welding current or speed.

Root Causes:

- Excessive Welding Current or Speed: Rapid welding without proper control.

- Incorrect Electrode Size: Inadequate filler material for the joint thickness.

- Poor Welding Technique: Uneven manipulation or erratic movement.

Elimination Strategies:

- Appropriate Settings: Adjust welding current and speed according to the joint requirements.

- Steady Hand: Maintain a consistent and steady welding technique.

- Correct Electrode Size: Match the electrode size to the joint thickness.

5. Slag Inclusions:-

Slag inclusions are solid, non-metallic materials trapped within the weld metal. They happen when slag, a residue produced during welding, isn’t entirely removed before the next weld pass is made.

Root Causes:

- Incomplete Slag Removal: Residual slag from previous passes.

- Incorrect Welding Technique: Improper arc length or travel speed.

- Poor Cleanliness: Contaminated base metal or filler material.

Elimination Strategies:

- Thorough Cleaning Between Passes: Ensure complete removal of slag before subsequent passes.

- Careful Technique: Control arc length and maintain a steady welding speed.

- Clean Base Metal: Ensure the base metal and filler material are free from contaminants.

6. Weld Spatter:-

Weld spatter is made up of tiny droplets of molten material that get ejected from the welding area and stick to nearby surfaces. Although it normally doesn’t impact structural strength, spatter does lead to an unpleasant finish and can be tedious to remove.

Root Causes:

- Incorrect Equipment Settings: Poorly adjusted welding parameters.

- Use of Damp Electrodes: Moisture present in the electrode coating.

- Incorrect Shielding Gas Flow: Inadequate or excessive shielding gas.

Elimination Strategies:

- Fine-Tuning Equipment: Optimize welding parameters for minimal spatter.

- Dry Electrodes: Store electrodes in a dry environment to prevent moisture absorption.

- Optimized Shielding Gas: Adjust gas flow to achieve effective coverage without waste.

Detection and Inspection of Welding Defects:-

To guarantee the quality and safety of welded structures, it’s essential to conduct regular inspections using non-destructive testing (NDT) methods. While visual inspection is the simplest approach, more in-depth insights can be obtained through techniques like ultrasonic testing, radiographic testing, and magnetic particle inspection. These methods are invaluable for detecting defects that may not be visible to the naked eye, enabling prompt remediation before issues escalate

Repairing Welding Defects:-

When defects are identified, whether to repair or redo a weld depends on factors such as the type of defect, its size, and the criticality of the application. Repair strategies typically entail removing the defective section and re-welding it under optimal conditions. Following precise repair protocols is crucial to guarantee the integrity of the weld.

Preventative Measures and Best Practices:-

Preventing welding defects begins with thorough preparation, which includes carefully selecting materials and ensuring proper surface cleaning. Welders should receive training in the correct techniques and settings tailored to their specific tasks. Additionally, regular maintenance of welding equipment is essential for minimizing defects and ensuring optimal performance.

Conclusion

Understanding and addressing common welding defects is crucial for ensuring the safety and durability of welded structures. By becoming familiar with the various types of defects, understanding their causes, and learning effective remediation strategies, welders and inspectors can greatly enhance the quality of their work. Adhering to best practices and embracing a mindset of continuous learning will further elevate welding outcomes, thereby safeguarding the integrity of structures worldwide.

You can watch this video about Welding defects: “Welding Defects (Animation)” by the YouTube channel AniMech.

For more informational content, please visit my website: Gyaanpool.com

For more information on Welding defects, please visit the page: Wiki.

You can also, visit my YouTube channel-Feather