Are you familiar with NDT in Welding? The term “NDT” refers to Non-Destructive Testing. The name is derived from its functionality: it enables us to examine objects without causing any harm. Think about the capability to inspect or assess the welding quality without causing any damage to the material or the completed work. That is the very essence of NDT in Welding.

It is a beneficial method for identifying any external or internal defects or contaminants in welds, resulting in time and cost savings, while ensuring the strength and safety of the welds. Non-destructive testing (NDT) plays a crucial role in industries such as construction, manufacturing, and oil and gas by ensuring the dependability and safety of various components. This guide aims to simplify the understanding of NDT. We will explore the significance of NDT in welding, clarify common misconceptions, examine several techniques, their procedures, advantages, and disadvantages, and anticipate future advancements.

Table of Contents

Breaking Misconceptions

A common misconception regarding NDT in welding is that it is time-consuming and costly. However, it is a fact that making an initial investment in NDT can result in significant time and cost savings in the future. It is like fastening your seatbelt before driving—it prevents defects and guarantees exceptional quality. According to the general opinion, non-destructive testing (NDT) should be applied to all welded components in order to ensure compliance with quality requirements, regardless of their prominence.

Types of NDT Techniques in Welding:

There are numerous NDT techniques available, but in this tutorial, we’ll focus on the eight that are most commonly used. Each method possesses its own distinct expertise; certain methods are capable of identifying both external and internal problems, whereas others are more effective at detecting only surface defects. In addition, particular methodologies are most effective when applied to specific substances. For example, magnetic particle non-destructive testing (NDT) is ideal for materials that have reactivity towards magnets. Without any additional delay, presented below are the eight most prominent non-destructive testing (NDT) techniques: –

- Visual Inspection (VT)

- Dye Penetrant Testing (PT)

- Ultrasonic Testing (UT)

- Radiography (RT)

- Magnetic Particle Testing (MT)

- Acoustic Emission Testing (AE)

- Eddy Current Testing (ET)

- Leak Testing (LT)

● Visual Inspection (VT)

Visual inspection is a straightforward technique used in non-destructive testing (NDT) to assess materials and welds. It is similar to visually inspecting something. During the course of this inspection, the examiner has the ability to identify external imperfections such as cracks, porosity, spatter, craters, and undercuts. In order to accomplish this, individuals may employ bright torches when they are indoors or choose to conduct remote visual examinations utilising cameras or drones in inaccessible regions. Visual examination is uncomplicated, cost-effective, and provides immediate feedback.

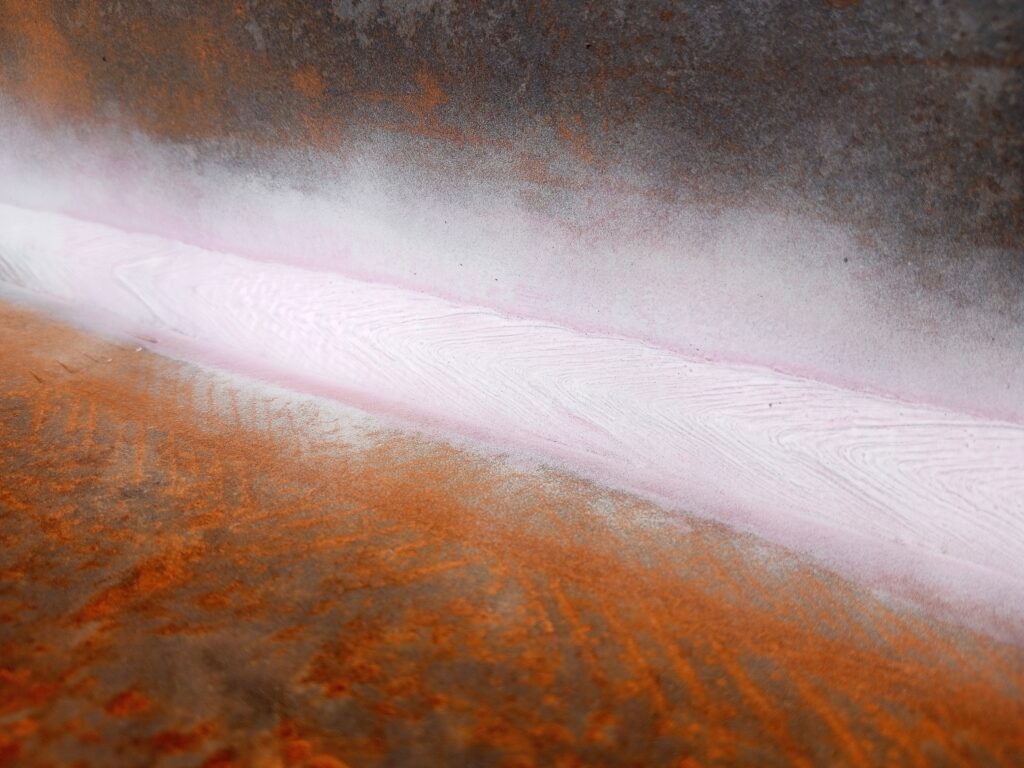

● Dye Penetrant Testing/Liquid Penetrant Testing (DPT/LPT)

The technique of liquid penetrant testing, also commonly referred to as dye penetrant testing, is a convenient and non-destructive approach utilised to detect imperfections on the surface of welded joints. The process involves the application of a specialised liquid dye over the surface, which penetrates any cracks, porosities, or craters. This test utilises the phenomenon of capillary action, wherein the liquid is attracted to narrow regions due to the influence of surface tension. The NDT method is commonly used due to its user-friendly nature and its remarkable versatility in various scenarios.

● Ultrasonic Testing (UT)

Ultrasonic testing is the most common non-destructive technique for identifying internal irregularities or defects. The detection of internal flaws in welded joints is achieved through the utilisation of high-frequency sound waves. Ultrasonic testing possesses high sensitivity, which allows it to accurately identify problems like incomplete fusion and slag inclusions with amazing precision.

The process involves directing high-frequency sound waves towards the thing being examined. If there’s anything defective within the material, the sound energy reacts in three ways. A portion of it returns to the origin, another portion gets absorbed by the substance, and the rest continues on its trajectory.

Ultrasonic testing employs two approaches to identify these flaws. The pulse-echo method monitors the energy that bounces back, requiring access from only one side of the item. Meanwhile, the through-transmission method evaluates the energy that passes through the material and requires access from both sides. Both methodologies offer significant contributions to assessing the integrity of welded joints, thereby guaranteeing their compliance with the most rigours standards of quality and safety.

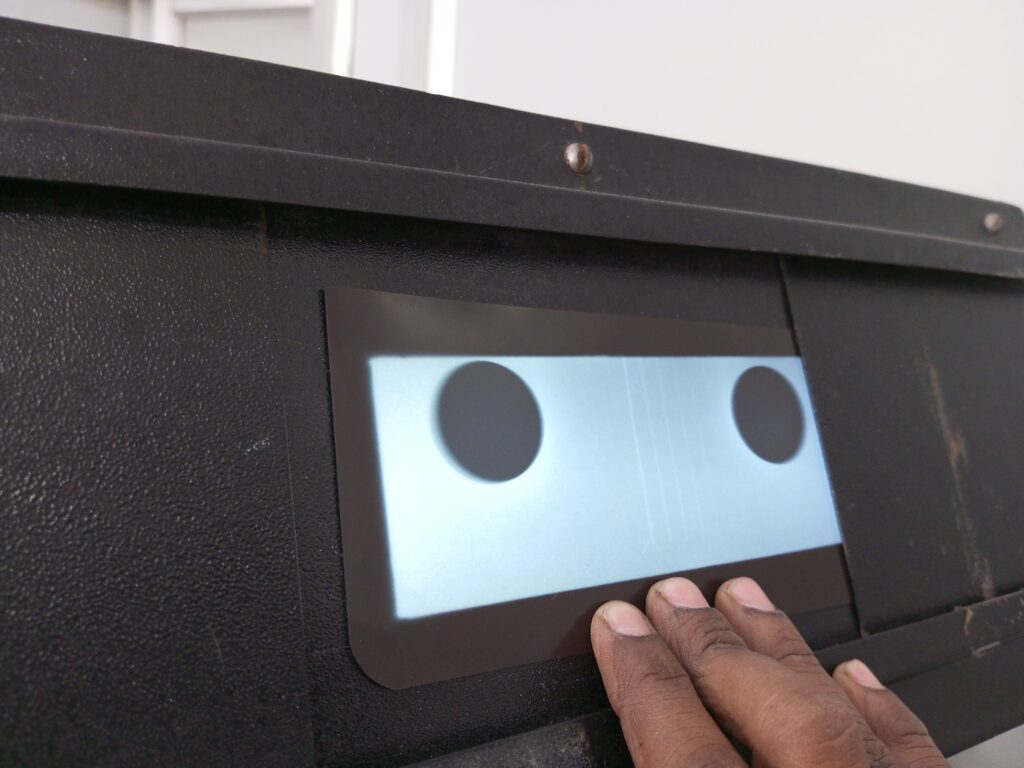

● Radiography Testing(RT)

Radiographic testing (RT) utilises X-rays or gamma rays to examine the internal structures of welded components. The act of looking through walls can be related to the process of uncovering invisible flaws, such as porosity, slag inclusions, incomplete fusion, or cracks, which may not be perceptible to the naked human eye. RT is widely used in several industries, such as aerospace, automotive, military, defence, and manufacturing, due to its capacity to detect internal faults.

However, RT is not limited solely to welding inspection; it is a versatile instrument that is extensively utilised in diverse industries. Radiography is essential for guaranteeing the quality and integrity of many constructions and goods, including pipes, pipelines, concrete, machined parts, metal components, and flat materials.

● Magnetic Particle Testing (MPT)

Magnetic particle testing (MPT) is an essential non-destructive testing (NDT) technique specifically developed to identify flaws in welds. It focuses on detecting flaws on the surface and immediately beneath them in materials that possess magnetic properties (referred to as ferromagnetic materials). The process involves magnetizing the component being examined, followed by the application of magnetic particles. These particles gather in the immediate area of any imperfections, such as cracks or discontinuities, making them noticeable.

MPT is renowned for its rapid and uncomplicated implementation. Unlike several alternative non-destructive testing (NDT) methods, it does not require rigours surface preparation. These characteristics make MPT a popular choice in the area of non-destructive testing, with professionals from a variety of industries relying on its efficiency and dependability.

● Acoustic Emission Testing (AE)

Acoustic emission (AE) is a technique used to identify and examine the acoustic signals produced by materials experiencing deformation. AE, or acoustic emission, is a technique employed in welding to continuously assess the soundness of welded connections by identifying signals linked to the development or spread of cracks. AE makes use of the capture and analysis of acoustic signals to detect faults at an early stage, allowing prompt corrective measures to be implemented.

● Eddy Current Testing (ET)

Eddy Current Testing (ET) is a multidimensional non-destructive testing (NDT) method that uses electromagnetic induction to examine conductive materials for both surface and subsurface imperfections. ET is frequently employed in welding to identify surface cracks, porosities, and other irregularities in welded joints. ET involves the generation of eddy currents in a material by using an alternating current flowing via a coil. These eddy currents exhibit distinct interactions with defects, enabling their detection and evaluation.

● Leak Testing (LT)

The purpose of leak testing is to verify the structural integrity of welded joints by identifying any instances of leakage or breaches inside the welded structure. LT procedures, such as pressure testing or vacuum testing, are employed in welding applications to pressurise or evacuate the welded component and observe for any sudden decreases or alterations in pressure, which indicate the existence of leaks. Leak testing (LT) plays a vital role in evaluating the integrity of welded joints, especially in high-stakes scenarios like pressure vessels, pipelines, and storage tanks.

Techniques and Procedures for NDT in Welding

● Preparing for NDT in welding

Before undertaking non-destructive testing (NDT) inspections, it is essential to clean the surface of welded components in order to guarantee precise outcomes. Adequate illumination and precise calibration of equipment are crucial for the effective execution of NDT testing.

● Conducting NDT inspections

During NDT inspections, qualified technicians inspect welded joints for faults using the specified technology. They stick to established methods and regulations to ensure thorough testing and accurate results.

● Interpreting NDT Results

Interpreting NDT results requires expertise and experience to distinguish between acceptable and unacceptable defects. Technicians analyse the findings and determine the next steps based on the severity of the defects.

● Reporting and Documentation of NDT Results

Upon concluding NDT inspections, professionals produce reports that document the findings, comprising specifics of identified flaws, their respective locations, and suggestions for remedial measures. Thorough documentation is necessary for the objectives of quality control and compliance.

● Importance of Training and Certification in NDT

Training and certification in Non-Destructive Testing (NDT) are essential to ensuring that technicians possess the requisite expertise and understanding to conduct inspections with precision. Certified NDT specialists follow industry standards and best practices, which improves the dependability of NDT results.

Advantages and Limitations of NDT in Welding

● Advantages of NDT in Welding

* Ensures the quality and safety of welded components

* Helps prevent costly repairs and failures.

* Detects defects early in the welding process.

* Increases confidence in the integrity of welded structures

● Limitations of NDT in welding

* Cannot detect all types of defects

* Requires skilled technicians for accurate results.

* Equipment and training can be costly.

* Limited by the accessibility of the welded joint

● Best Practices for Overcoming Limitations of NDT in Welding

* Use a combination of NDT techniques for comprehensive inspections.

* Invest in ongoing training and certification for technicians.

* Implement quality assurance measures throughout the welding process.

* Regularly review and update NDT procedures based on industry advancements.

Emerging Technologies in NDT for Welding

Technological advancements, including robotics, artificial intelligence, and automated NDT systems, are influencing the course of NDT in the field of welding. These technological advancements optimise the inspection procedure, enhance precision, and minimise human error.

Conclusion

In summary, non-destructive testing (NDT) plays a crucial role in ensuring the quality and structural integrity of welded constructions. Understanding the types, techniques, processes, benefits, limitations, and future developments of NDT in welding allows companies to maintain high levels of safety and reliability. Investments will influence the future of NDT in welding in training, certification, and developing technology, which will drive the industry toward innovation and excellence.

Resources for Further Reading

For more information on NDT in welding, check out the following resources:

* American Welding Society (AWS) NDT resources

* NDT Resource Centre

* International Organisation for Standardisation (ISO) NDT standards

———————————————————————————————————————-

For more informational content, please visit my website: Gyaanpool.com

For more information on Welding defects, please visit the page: Wiki.

You can also, visit my YouTube channel-Feather